At Vulcan, we use advanced, in-house metallurgy and state-of-the-art facilities to take metal and forge it into the ultimate value for our customers.

We raise engineering and design expectations by delivering consistent and repeatable results with every project. That’s because our in-house metallurgy lab enables us to build and test multiple options, narrowing down to the best of the best design before scaling up production.

Welcome to the cutting edge of steel. Advanced Stainless™ Steel is the product of rigorous research and development in metallurgy, bringing a level of quality otherwise unseen. This proprietary, high-performance material delivers higher yield and tensile strength, more elongation, greater hardness, and better energy absorption than any other stainless steel on the market. Now, we’re proud to make it a part of the solutions to our customers’ challenges.

Advanced Stainless Steel

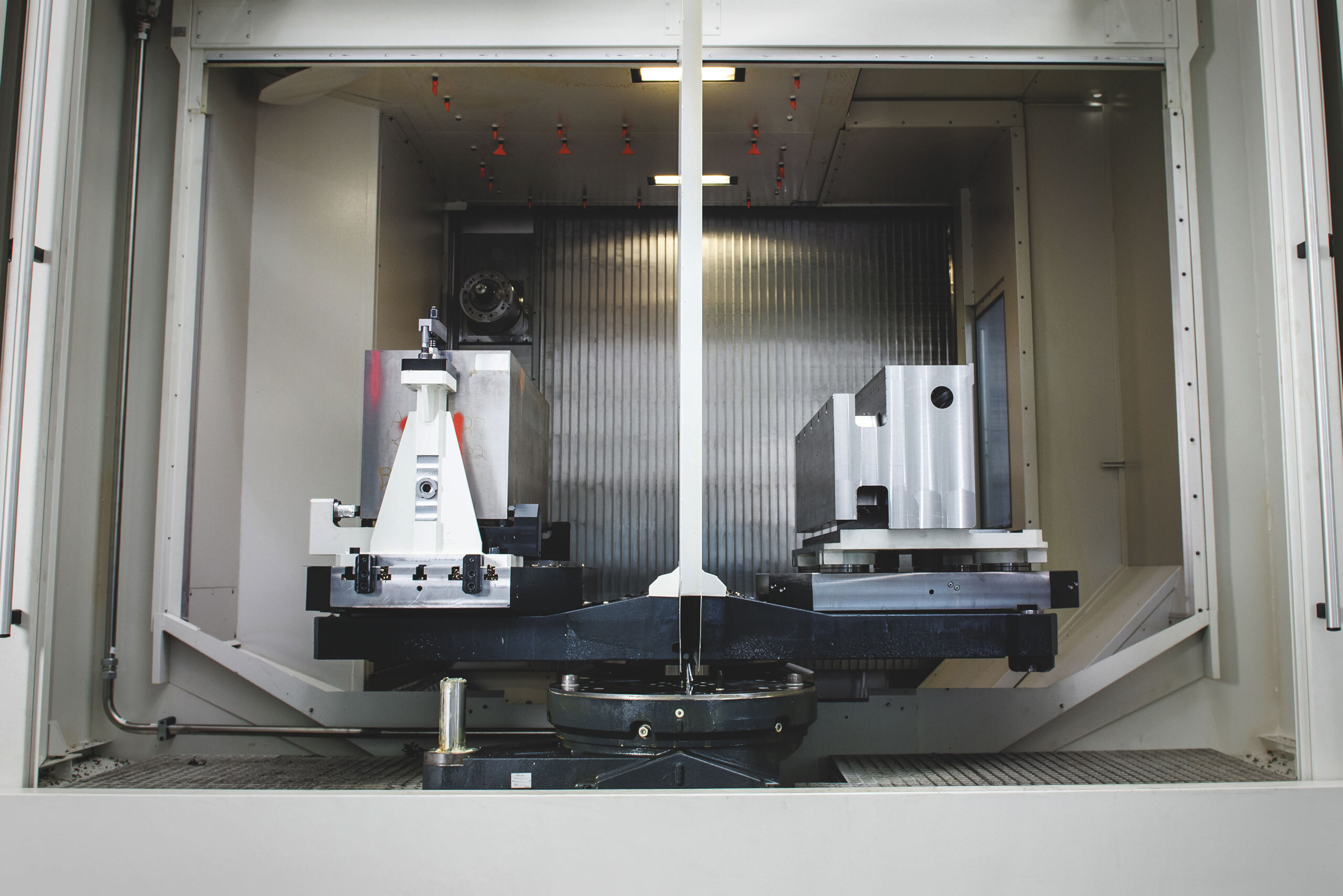

With in-house Ph.D. Material Science, two laboratories, and state-of-the-art facilities, Vulcan is positioned to provide innovative problem-solving that delivers more value. Over 30 percent of our staff are degreed engineers. So, high-performance problem-solving stays at the forefront of our minds across every business function. Our in-house testing capabilities mean Vulcan Industrial teams can fast-track successful results from prototype to field-ready designs far more quickly than our peers. This on-demand development data ensures that customers get only the best quickly.

With world-class manufacturing and engineering expertise and cutting-edge equipment, Vulcan is capable of rapid iteration in highly controlled environments. These decisive differentiating factors allow our team to go from a custom request to delivering a highly engineered, large, and complex product in under four months.