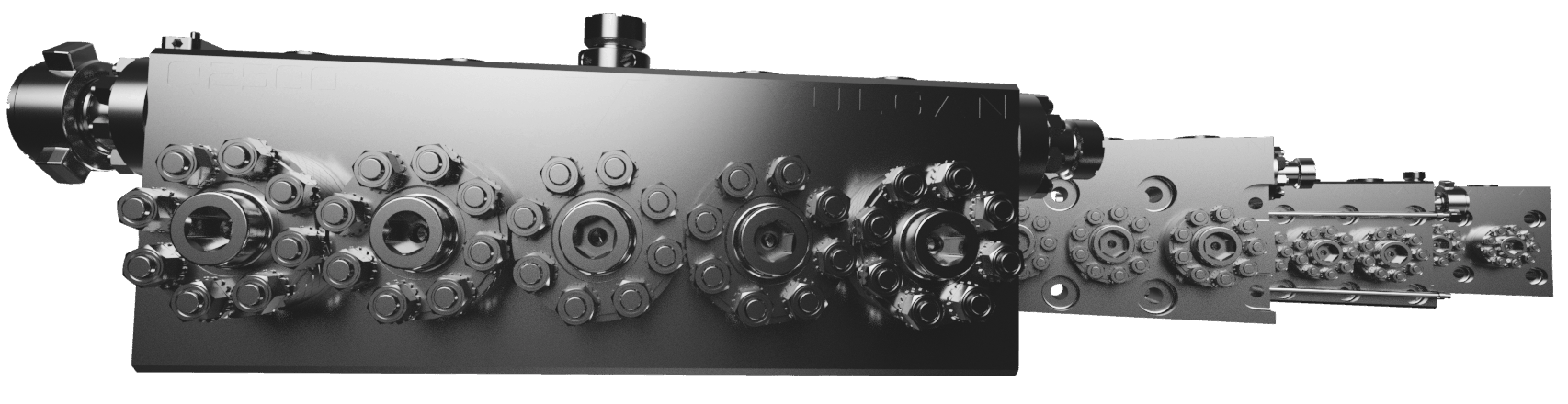

The Vulcan V-Series™ represents a level of fluid end technology above the rest, with cutting-edge engineering and advanced metallurgy. These products are engineered with our proprietary Advanced Stainless™ Steel and designed to meet higher expectations, deliver more value, and run longer in the field. See the difference the V-Series can make to your fleet by calculating your total cost of ownership at the link below.

V-Series™ can deliver best-in-class performance and ultimate field serviceability by combining the endurance of Advanced Stainless™ Steel with a design that features 50% fewer parts. That means operators can expect easier installs, cross-compatible components, and more reliable fluid ends built to address the challenges of today’s demanding pressure pumping operations.