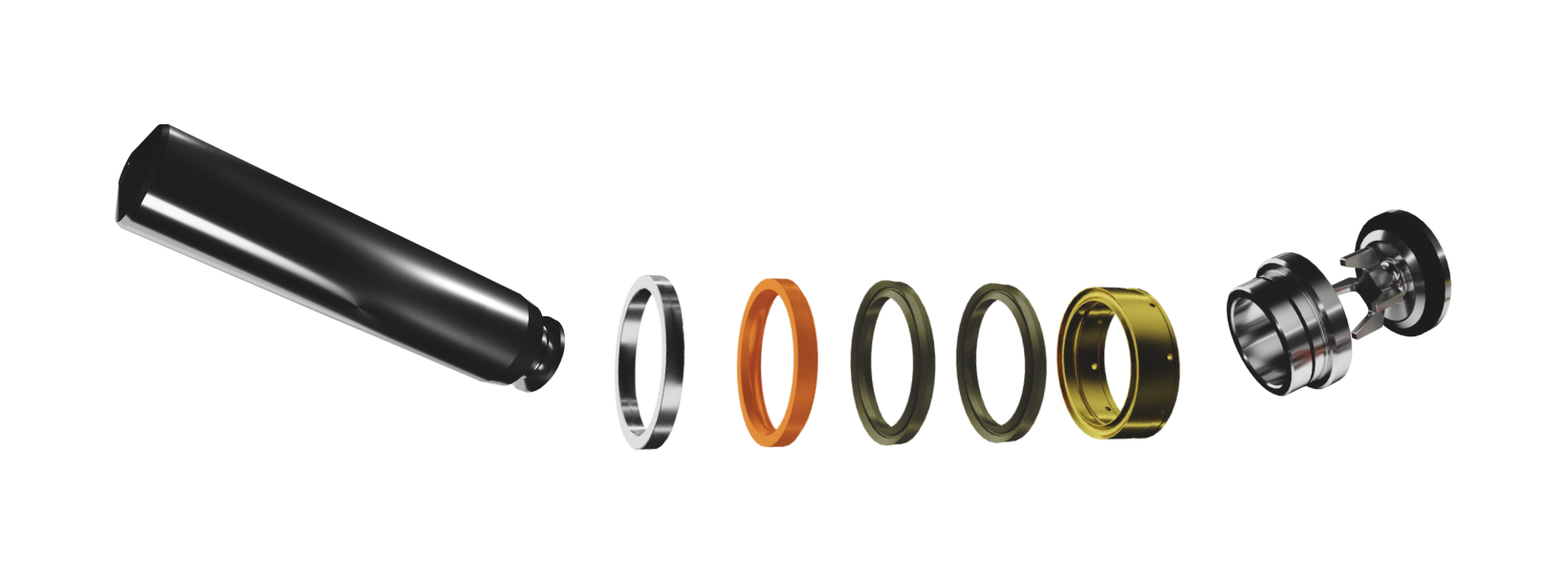

Our high-performance replacement products are designed to extend service life, bringing greater value to the field. That’s why all of our components are engineered with advanced nanograde composites that reduce friction and increase overall resistance to wear, tear and abrasion.

Vulcan keeps a large inventory of replacement parts in your area of operation

to keep you ready for anything.