Vulcan leverages advanced engineering and superior design to bring mission-critical performance and optimized economics to businesses that won’t settle for anything less than the best. Whether it’s in the field, in the ocean or on the launch pad, we deliver maximum value.

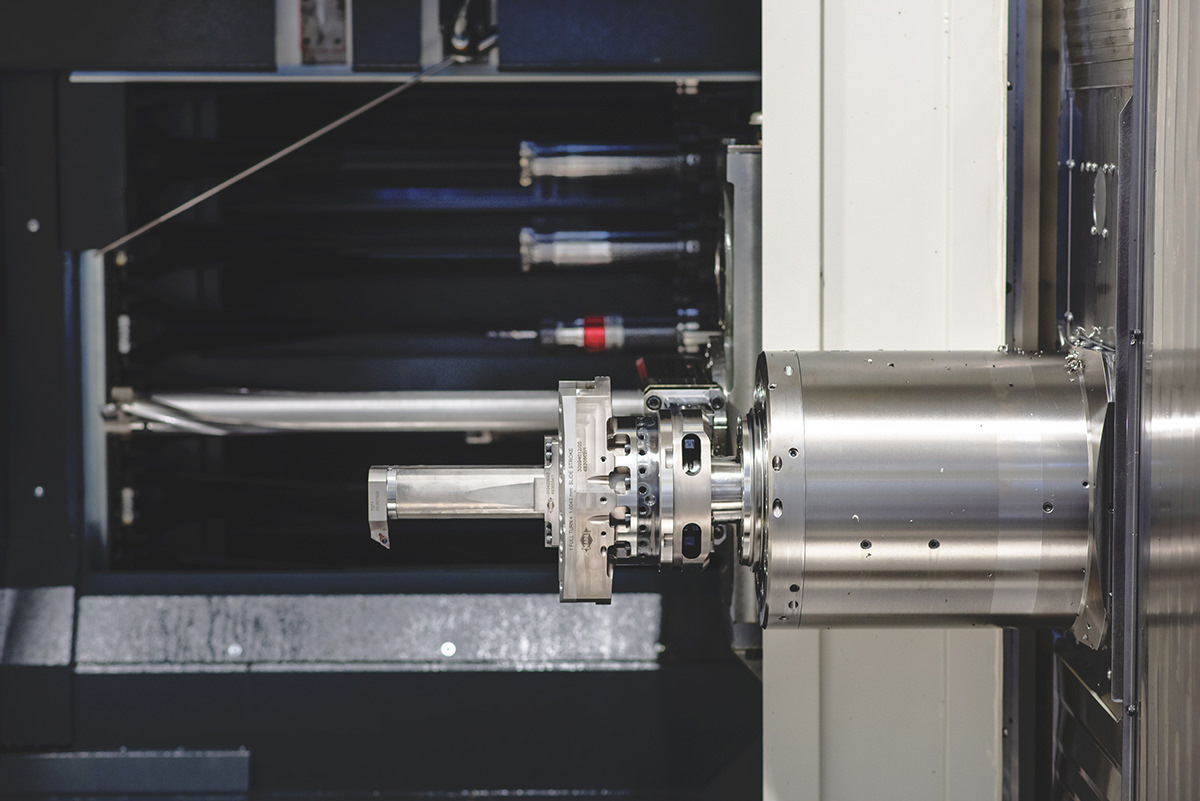

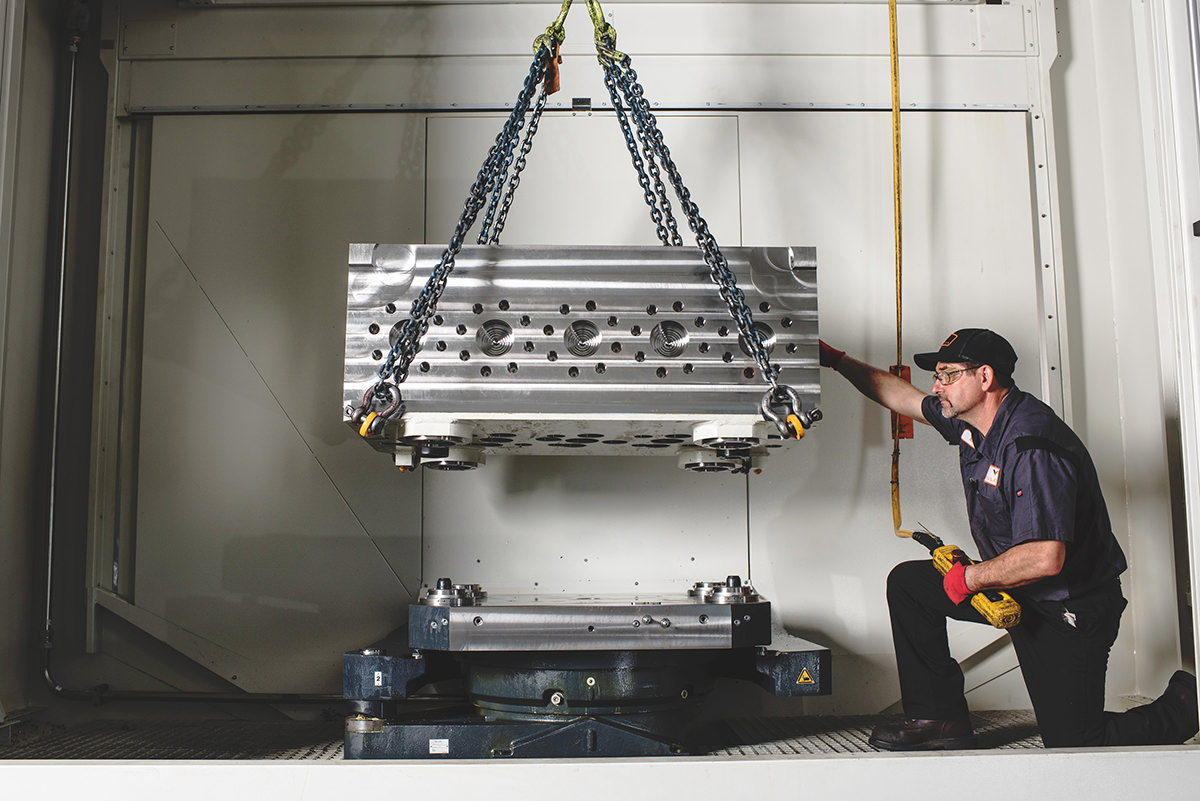

Our next generation manufacturing means strong quality control for our customers. From our state-of-the-art facilities and in-house metallurgy lab, to our teams of talented and dedicated personnel, Vulcan is uniquely positioned to provide unparalleled service and powerful solutions that bring lasting success.

Nobody does more for you than Vulcan. We make it our priority to deliver superior value and superior service to all our customers. That’s what sets us apart from the rest—it’s why Vulcan is trusted by the United States Armed Forces and companies on the forefront of the aeronautics, defense and energy sectors.